Description

Double Stem Hose Connector is a hydraulic piece that has two stems at its ends. ( Despite regular hose connector ends that mainly have nuts ) the stems merge into the hoses and fix securely. These fittings are permanent and, they are mainly useful to connect hoses with the same size or repair a damaged section of the hose. Generally, hydraulic hose fittings are divided into two main groups the fixed ones and replaceable ones. The Fixed hydraulic fittings are extensively used across heavy hydraulics since they install fast and easy compared to the replaceable fittings. Moreover, these fittings are often more economical also more trustable. Double stem hose connector is also classified as fixed hydraulic fittings.

Applications

light & heavy hydraulic applications within the Mining, defence, transport, agriculture, construction, industrial & marine industries for machinery & equipment. E.g. Harvesters, frontend loaders, skid steer loaders, mobile crane, feeders, drilling, hay rakes, balers.

Selection

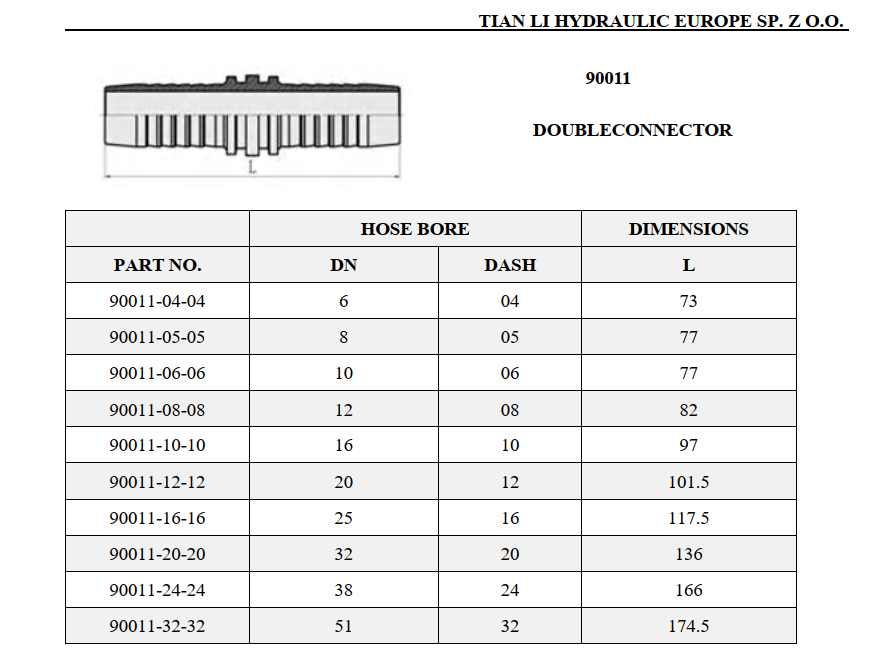

Double stem hose ends come in wide variety of sizes. According to the information table below and based on the pipe and hose sizes you can choose the most appropriate one.