TIAN LI HYDRAULIC EUROPE SP. Z O.O.

NL METRIC swivel nut L type

NL METRIC swivel nut L type

Dostupnost vyzvednutí nebylo možné načíst

NL METRIC swivel nut L type

24° Cone End Nut

QUICK OVERVIEW

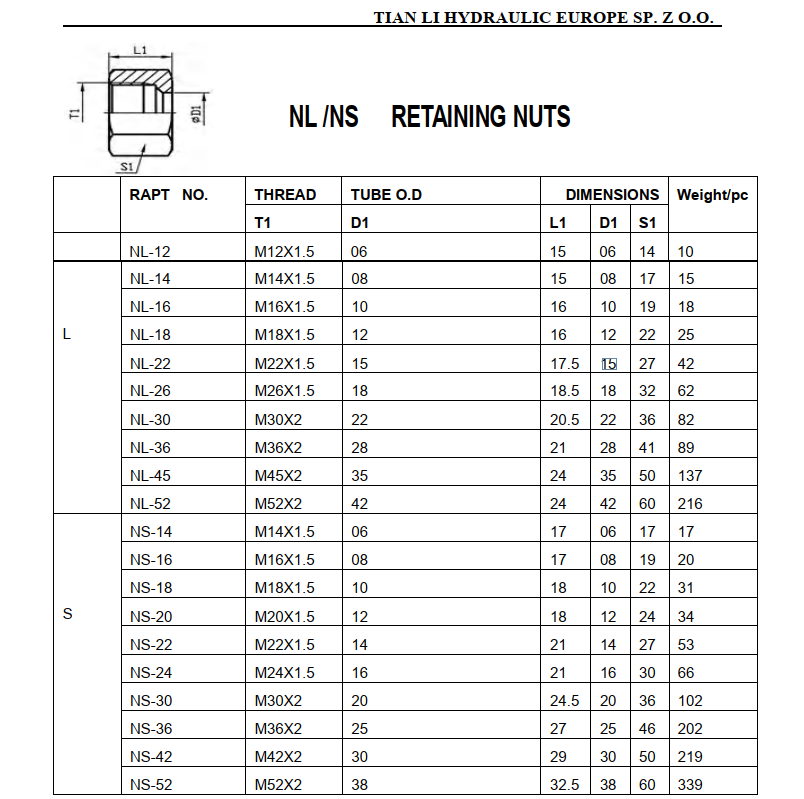

DIN 2353 Tube Nut for cutting ring connections is categorizing as DIN Connections in hydraulic systems. These nuts are designed as per DIN standard specifications with male thread type and 24° Cone seat. They are extensively useful across multiple applications in hydraulic systems. Mainly constructed from Carbon steel or Stainless Steel, the product is available in different sizes.

DIN 2353 Tube Nut Description

DIN 2353 Tube Nut for cutting ring connections is categorizing as DIN Connections in hydraulic systems. These nuts are designed as per DIN standard specifications with male thread type and 24° Cone seat. They are extensively useful across multiple applications in hydraulic systems. Mainly constructed from Carbon steel or Stainless Steel, the product is available in different sizes.

DIN type tube fittings conform to the requirements of ISO 8434-1, DIN 2353, and DIN EN 3850 standards, that ensures interchangeability among leading brands of fittings. DIN 2353 tube fittings are used in a wide variety of fluid power applications, especially in factories, oil & gas, and construction equipment. DIN2353 fittings are the most widely useful bite-type fittings in the world. Furthermore, they don’t require O-rings or other elastomers to make a leak-tight seal.

Selection

DIN 2353 Tube Nut comes in various sizes. Pay close attention to the correct size while selecting and installing the connectors. Before choosing the adapter, take the fluid volume, pressure, and other system properties into consideration. Different sizes for this adapter are available in the above information table. You can also check our other DIN 2353 Bite Type Adapters including a wide range with different shapes and sizes for making any desired connections.

Product Usage

First and foremost, the adapter selection should be according to your requirements. After choosing the proper adapter size based on the fluid volume, pressure, media, environmental situations, and other properties, you can install the adapter. Besides, we recommend contacting the supplier or the manufacturer for installation consultation.

Share